Polished Concrete

Polished Concrete from A to Z

Despite the many flooring options available, owners, developers, retailers, architects, engineers and even homeowners are choosing polished concrete as their finished floor choice. Aesthetics, uniqueness, the reduction in annual maintenance cost and light reflectivity are a few reasons why this flooring system is quickly becoming one of the most sought-after hard surfaces.

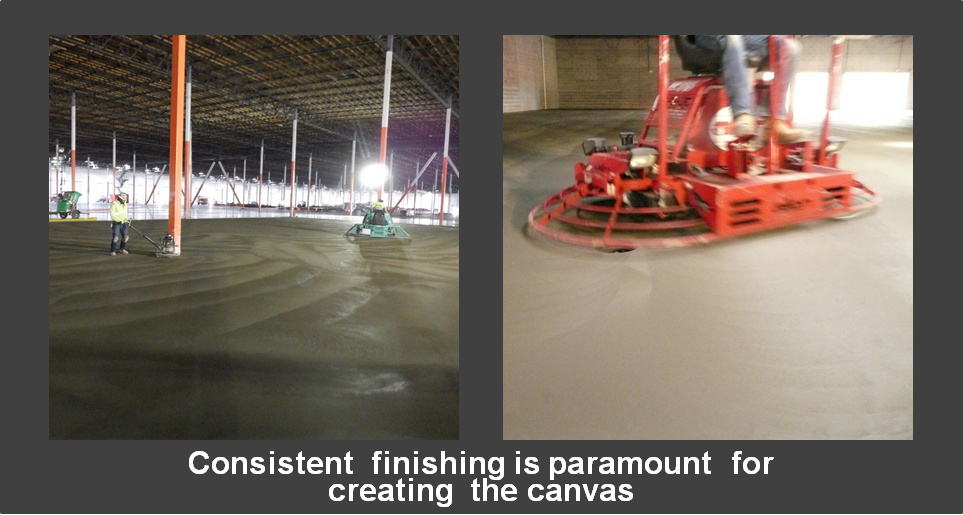

Concrete mix design review, slab placement and finishing

Annually, our team consults on millions of square feet of slab placements “Creating the canvas” as we call it which starts with the proper mix design. Not having the correct proportions of ingredients in the mix could lead to a very inconsistent polished surface. Specifying the proper mix design requirements, managing the conformance of the submitted design, and proper slab placement is paramount to a successful polished surface which our team can assist with.

Jobsite support

Our award winning team works with the place and finish crew with an understanding of what it takes to produce a uniform and consistent finish, specifically for polished concrete. Large slab placements can be challenging and having expertise onsite during the concrete placements can make the difference between ordinary and extra ordinary. Optimizing the final aesthetics of the polished concrete surface only begins with installing a flat floor. Minimizing cracks, finishing around plumbing and electrical fixtures with minimal differential in color can only be achieved with proper planning and understanding of modern finishing techniques.

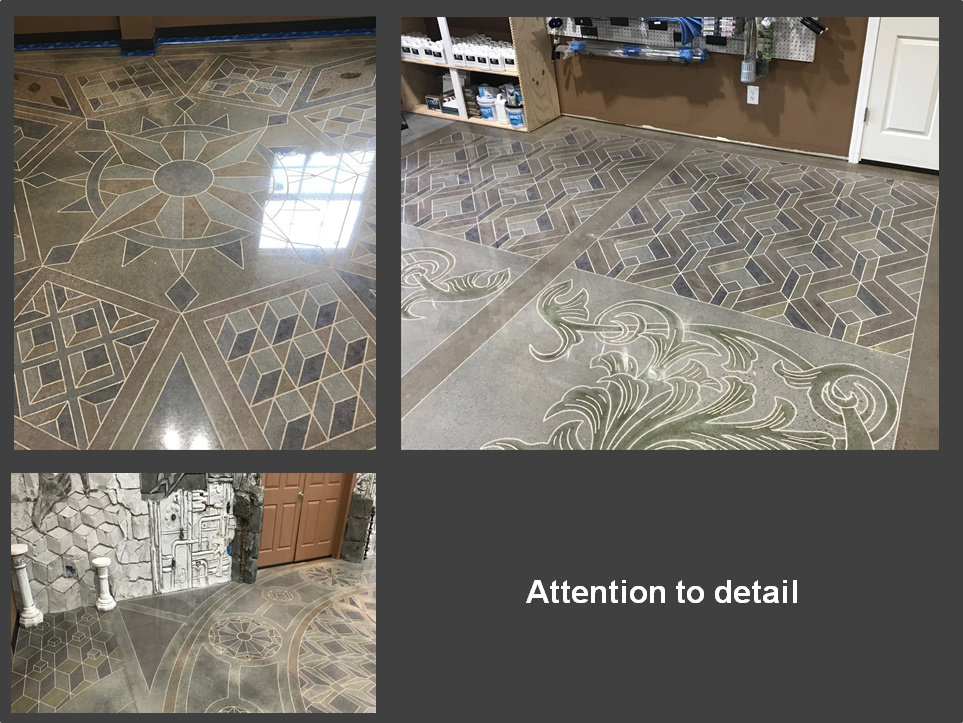

Condition survey

There are many different challenges during a slab placement that can arise sometimes resulting in areas that need to be repaired. While on site, our team can perform a complete condition survey of any questionable areas that could impact the aesthetic of the finished polished surface such as gouges, cracks full depth repairs, differential finish, and cure lines.

Prescribe

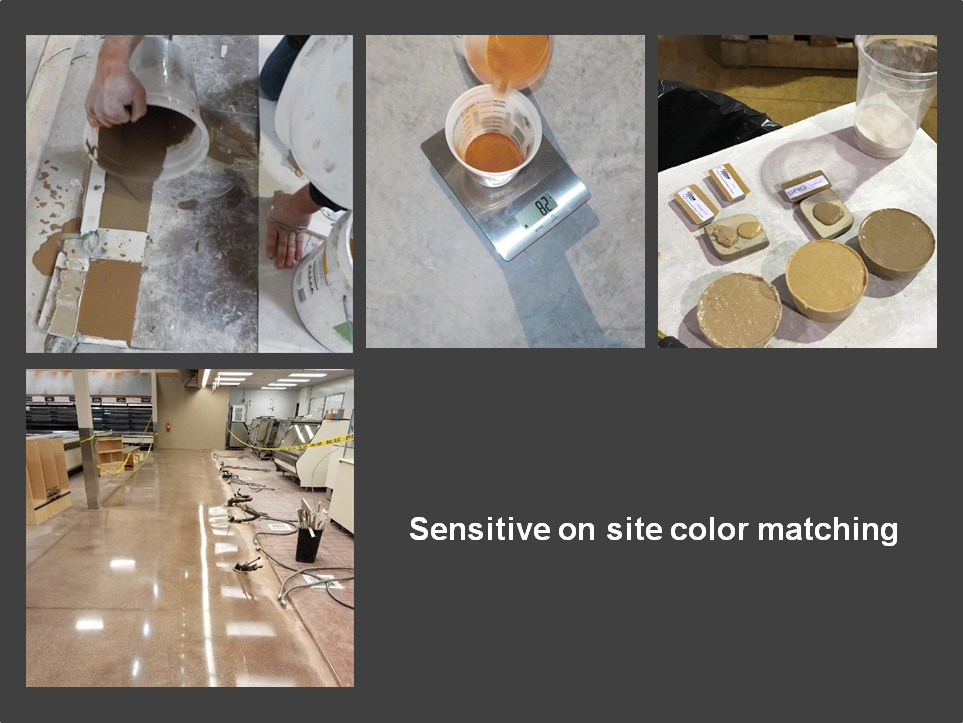

With many potential surface conditions, unfortunately, repairs are not a one size fits all. The two main considerations with repairs are serviceable integrity and aesthetics. Prescribing the appropriate repairs utilizing proper products and coloring techniques can have a huge impact on the finished polished surface.

Educate

SSI works closely with the polishing contractor sharing our over 23 years of field experience overcoming challenging situations that may arise on a project. Often, critical decisions need to be made on the fly that can dramatically impact the overall project. Finding solutions while working together sharing the same common goal of producing the best polished surface can make a difference on your project.

Observe

Producing polished concrete mockups are an important aspect of any retail or commercial project to establish a realistic expectation of what can and cannot be achieved on each individual surface. With polished concrete specifications, equipment and installation techniques evolving through the years, it is crucial that the polishing contractor is meeting the expectations of the client. We will chronicle and document every step of the entire process and in some cases, oversee the first several days of production polishing.

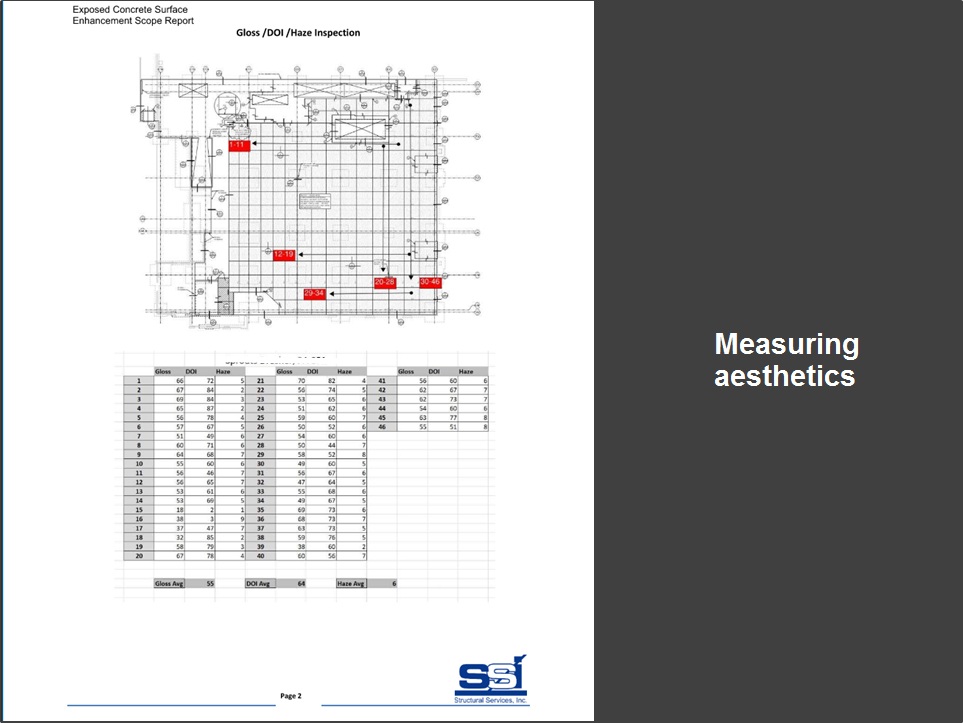

Reports

Accurate reporting is an important aspect of any project. Quick turnaround times on reports adds value to the project especially if there are issues needing to be addressed while the polishing contractor is on site performing their work. Also, having detailed reports gives the client the ability to reference their archived projects to collect any information they may need.

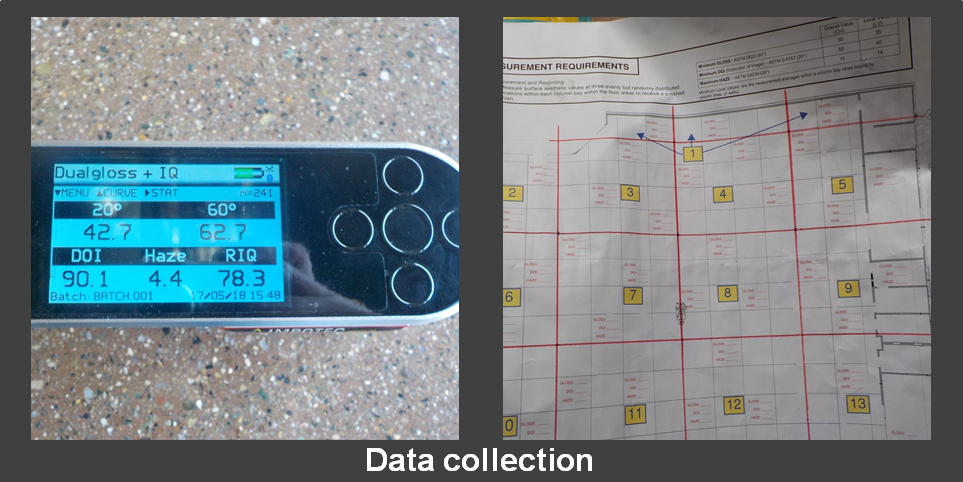

Measuring Aesthetics

Validation of the completed project is important to make sure the client is getting the best possible result while meeting the specified requirements. For most clients, SSI’s technicians return while the polishing team is still on site to collect measurables such as gloss, DOI and haze readings. During this site visit, a condition survey of the finished floor is performed identifying punch items that can be addressed while the polishing team is still onsite saving re mobilization fees and time. Only with proper measurements and assessment can an owner objectively define and validate aesthetic expectations.